The dresser that I inherited had two big drawers with broken knobs. I was hoping to use it in my attempt to organize my sewing room. It was well made, but wooden knobs can only handle so much 6 foot teenage boy. My engineer surprised me a few days ago with a new, very sturdy, PVC pipe drawer handle on one of them. He demonstrated how smoothly it pulled the drawer open using only one hand, and asked me if I liked it. I was very pleased. He asked if I wanted to see how he made it.

Materials used:

- length of one inch PVC pipe – it is useful to note that this is the inside diameter, the outside is closer to 1.25 inches.

- something to cut spacer pieces out of, approximately 1.25 inches long, optional

- two 4 inch screws of a size that will fit through the holes that already exist in the drawer, which was #8 in this case

- two nuts to fit on the end of the screws, extra if using them instead of spacers

Equipment used:

- table saw

- regular drill

- drill press

- scraps of wood

- shop clamps

- vice

- shop knife

- grinder

- sand paper

First, he measured the distance between the holes already in the drawer. The handle needed to be a bit longer than that by approximately a couple of inches on each end. He had a scrap piece of PVC pipe that could be cut in half to give two pieces of good length. He measured the extra distance, divided it by 2, then measured that divided distance from each cut end of PVC pipe, marking it with pencil. (click on any photo to enlarge)

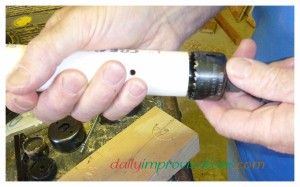

It was helpful to have a guide to hold the round PVC pipe in place under the drill press. For this, a rounded ditch was cut in a length of scrap wood. A mark was made in the center bottom of this ditch at one location. The scrap wood was held in place with two other pieces of wood clamped in place to hold it, the drill press bit being positioned to verify alignment. When the PVC pipe was put in the guide, it did not roll away and it was much easier to drill exactly where it was marked.

It was simple enough to drill a hole straight through one end of the PVC, but it takes more care to make sure the second holes line up with the first ones directionally. The PVC pipe was laid against the hinges of the door being used as part of his shop table. Anything that will keep it from rolling, plus providing a clear edge to measure from, would do. He placed the pipe with the first hole facing him and measured how far up from the edge of the side of the door it was. Then, he went over to the other end of the pipe and measured that same distance from the edge of the door near where the mark for distance from the end was. This showed an intersection where the second hole should be drilled.

Now would be a good time to spray paint the PVC pipe, if color matters to you. There are spray paints formulated to adhere to plastic, available at places like Home Depot and Walmart. This is what we used for the hanging rod for some of my greenhouse lights. If you click on this link you can see that the painted PVC pipe looks like shiny, black metal. This was not important to me in my sewing room, where everything is eclectic and I have many white plastic drawers.

Some spacers were made, to hold the PVC pipe handle out from the face of the drawer. My engineer had some thick plastic that he wanted to use (available to him at a company’s clean trash pile). He said some wood would work just as well. The spacers could be skipped all together by just screwing a nut on to keep the PVC pipe handle at a proper distance. If some material is used to create a spacer, one end needs to be cut to a curvature that will fit on the PVC pipe. He did this by comparing hole saws to the PVC pipe. When he found one the correct size, he attached it to a regular, hand held drill to cut a circle through the plastic. The other end of each spacer piece can be flat, to fit up against the face of the drawer.

Cutting the plastic spacers to the correct dimensions was done by:

1. Making sure the circle was cut at a distance from one end, so that one spacer would already be the correct length.

2. Using the table saw to make two grooves not quite all the way through one side of the plastic, guided by the table saw ‘fence’, that were spaced as far apart as the desired final width of the spacers. Doing this before the second spacer was cut to size leaves a place to hold for guiding the plastic through the saw.

3. Saw the other end of the plastic off at an appropriate distance from the circle, so that both spacers are the same length.

4. The spacers need holes drilled all the way through them and it works better do to this before the pieces get too small. A drill press makes this easy, because it will drill straight down. Since the drill press bit is held firmly in position it works to hold the plastic perpendicular against the drill plate. My engineer held it carefully by hand. If a regular drill is going to be used, then it would be safest to set up something with a vice or clamps to hold it. Flip the piece over to drill the other end.

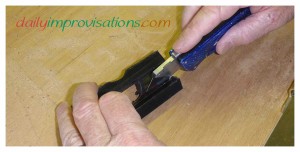

5. Put the grooved plastic horizontally in the vice, between 2 pieces of scrap wood to keep it from getting scratched, then snap it to one side, to almost completely break the extra width off of the plastic. Turn it around and do it to the other side.

6. Use a shop knife to cut through the last thin bit of plastic, to break it completely into the parts.

7. Grind off the rough edges of the plastic using the grinder and sand paper as needed.

8. Peel of the protective plastic coating that was on the shiny front of the plastic.

Now, all that needs to be done is screw it all to the drawer face. The screw is put through the PVC pipe, then the spacer, then lastly, through the hole in the drawer. A nut is screwed on the end sticking through to the inside of the drawer. If the PVC pipe was painted black, you probably want to paint the screw head black, too. Another option is to buy caps to finish the ends of the pipe, again painting them black if that is the color scheme.

The diameter of the pipe feels quite comfortable in the grip. The handle can be grasped anywhere along its length to pull it open. Now I have no qualms about filling up those big drawers to capacity.